The Revolutionary Impacts of 3D Printing on Business

3D printing technology has been rapidly transforming the landscape of various industries, and its impact on businesses has been profound. From rapid prototyping to customized manufacturing, 3D printing has opened up a world of possibilities that were once considered science fiction.

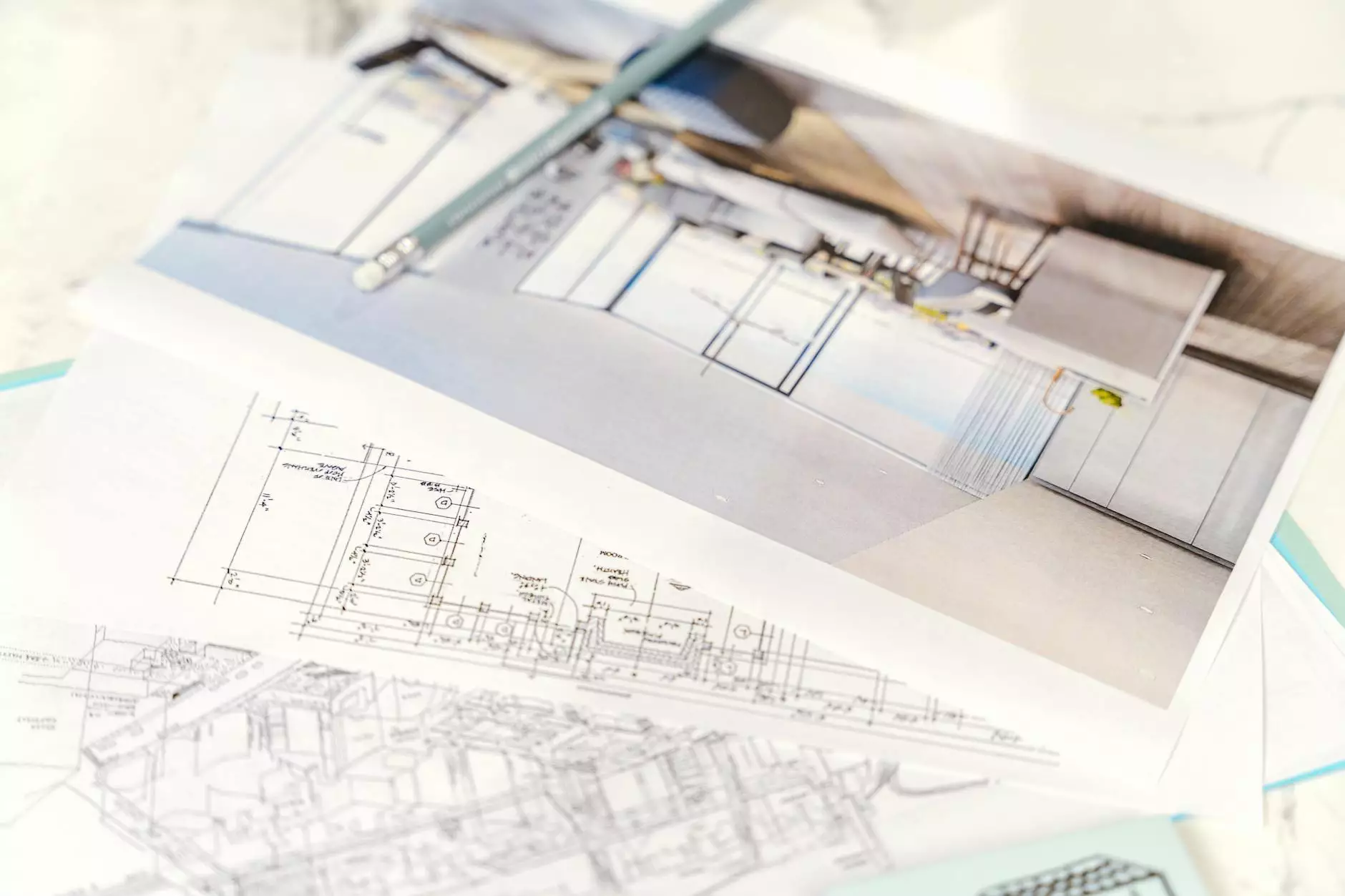

Revolutionizing Manufacturing Processes

With 3D printing, businesses can now create prototypes and products with unprecedented speed and precision. The ability to directly translate digital designs into physical objects has significantly reduced the time and cost associated with traditional manufacturing processes. This has not only accelerated product development cycles but also enabled businesses to bring innovative ideas to market faster.

Customization and Personalization

One of the key advantages of 3D printing for businesses is the ability to offer customized and personalized products to consumers. From jewelry to medical devices, 3D printing allows for intricate designs and unique configurations that cater to individual preferences. This level of customization not only enhances customer satisfaction but also opens up new revenue streams for businesses.

Cost-Effectiveness and Waste Reduction

3D printing technology has the potential to significantly reduce material waste and production costs for businesses. Traditional manufacturing methods often result in excess materials that go to waste, but with 3D printing, objects are built layer by layer, minimizing material wastage. Additionally, businesses can produce complex geometries and small batches economically, making it a cost-effective solution for small-scale production runs.

Enhancing Supply Chain Management

Integrating 3D printing into supply chain management can streamline processes and reduce lead times for businesses. By leveraging on-demand manufacturing, businesses can produce parts and components as needed, reducing inventory costs and minimizing the risks associated with stock shortages. This flexibility in production allows for just-in-time manufacturing and greater supply chain resilience.

3D Printing in the Road Sweeper Industry

When it comes to the road sweeper industry, 3D printing has the potential to revolutionize the way road sweepers are designed and manufactured. Road sweeper components that require intricate designs and precise specifications can be prototyped and produced using 3D printing technology, resulting in enhanced performance and durability of the machines.

Cost Considerations for Road Sweepers

Road sweeper cost is a crucial factor for businesses in the road cleaning industry. With 3D printing, businesses can explore cost-effective solutions for producing road sweeper components. By leveraging 3D printing technology to prototype and manufacture parts, businesses can optimize costs and improve overall efficiency in road sweeper maintenance and operations.

Future Outlook

As 3D printing continues to advance and evolve, businesses across various industries, including road sweeping, will likely experience further advancements in design capabilities, customization options, and cost efficiencies. Embracing 3D printing technology can position businesses for success in an increasingly competitive and innovation-driven market landscape.

Conclusion

In conclusion, the impacts of 3D printing on business are far-reaching and transformative. From enhancing manufacturing processes to enabling customized solutions, 3D printing offers businesses the tools they need to stay ahead in today's dynamic marketplace. As businesses look towards the future, incorporating 3D printing technology can unlock new opportunities for growth, efficiency, and sustainability.